VOLVO VCS 1029,54719高壓蒸汽噴射試驗(yàn)

| The English language version is the original and the reference in case of dispute. | 英文版本為原件,出現(xiàn)爭(zhēng)議時(shí)應(yīng)予以參考。 |

| TEST METHOD | 測(cè)試方法 | ||

| Adhesion, water spraying under high-pressure | 粘附性,高壓噴水 | ||

| Paints and enamels | 涂料和搪瓷 | ||

| Orientation | 簡(jiǎn)介 | ||

| This issue differs from issue 1 in that an alternative for when scribing shall be made has been included. Furthermore, the manufacture of the spray nozzle has been specified, and the material for calibration has been changed. Handling after moisture exposure has been clarified. |

本版本與第1版的區(qū)別在于包含了劃線(xiàn)的替代方法。 此外,已經(jīng)規(guī)定了噴嘴的制造程序,已經(jīng)更改了校準(zhǔn)的材料。已經(jīng)澄清了暴露于潮濕環(huán)境后的處理程序。 |

||

| 1 Scope and field of application | 1 應(yīng)用范圍和領(lǐng)域 | ||

| This test method is used for assessing the adhesion between paint films and between paint film and substrate respectively. The method is intended to simulate the strain and load that the paint films are subjected to during high-pressure cleaning. | 本測(cè)試方法用于評(píng)估漆膜之間以及漆膜和基材之間的粘附性。本方法預(yù)計(jì)用于模擬漆膜在高壓清洗條件下可能受到的應(yīng)變和負(fù)載。 | ||

| 2 Apparatus and test object | 2 裝置和測(cè)試對(duì)象 | ||

| - Test equipment of high-pressure type, brand NIFAB, model HTT-1, or equivalent test equipment | - 高壓型測(cè)試設(shè)備,NIFAB牌、HTT-1型,或者其他等效測(cè)試設(shè)備 | ||

| Water pressure: | min. 150 bar | 水壓: | *低150巴 |

| Spraying distance: | 0-150 mm | 噴射距離: | 0-150mm |

| Sweeping frequency: | 1 sweep/s | 清掃頻率: | 每秒清掃一次 |

| Water temperature: | 50 ± 5 °C | 水溫: | 50 ± 5℃ |

| Spray nozzle: |

No 2506 (flat jet 25°) Spraying Systems Co. |

噴嘴: | No 2506(扁平射流25°),由Spraying Systems Co.生產(chǎn) |

| Lance length: | 300 ± 50 mm | 噴桿長(zhǎng)度: | 300 ± 50 mm |

| Test piece holder withcentre hole, size of hole: | Æ 40 mm | 帶有中心孔的試樣固定器,孔徑為: | Æ 40 mm |

| - Test object |

|

||

| a) Test panel 100 x 200 mm of the substrate in question, surface coated with the relevant paint system. A minimum of two panels shall be tested. A minimum of three crosses distributed between the two panels shall be tested. | a) 測(cè)試面板,100 x 200 mm(相關(guān)基材);表面涂有相關(guān)的涂料系統(tǒng)。至少測(cè)試兩塊面板。至少測(cè)試分布于兩塊面板之間的三道十字標(biāo)記。 | ||

| b) Test part of the relevant substrate, surface coated with the relevant paint system. In order to have significant results, test pieces should be taken from different areas on at least two test parts. A minimum of four crosses shall be tested for each part. | b) 測(cè)試零件(相關(guān)基材),表面涂有相關(guān)的涂料系統(tǒng)。為了獲得顯著性結(jié)果,至少應(yīng)從兩個(gè)測(cè)試零件上的不同區(qū)域采集試樣。每個(gè)零件至少測(cè)試四個(gè)十字標(biāo)記。 | ||

| - Scribing tool, edge width 0,5 mm and geometry according to VCS 1021,29. |

|

| 3 Preparation for test | 3 測(cè)試準(zhǔn)備 |

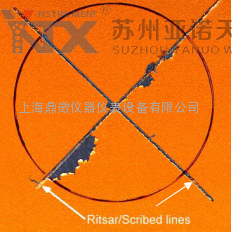

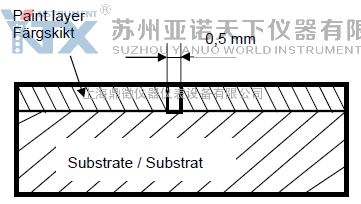

| The test panels shall be conditioned in accordance with VCS 1021,19. Before testing the adhesion, an initial paint damage shall be made on the test object by scribing two 0,5 mm lines using a scribing tool. The scribed lines shall be made down to the substrate, at right angles to each other to create a cross, see fig. 1. The scribed lines shall extend outside the test area. Each scribed line shall be approx 60 mm. A cross section of a scribed line is shown in fig. 2. importANT – The edges of the scribed lines must be at right angles to the substrate. |

應(yīng)按照VCS 1021,19的要求對(duì)測(cè)試面板進(jìn)行調(diào)節(jié)。測(cè)試粘附性前,應(yīng)使用劃線(xiàn)工具在測(cè)試對(duì)象上劃兩根0.5mm的線(xiàn),作為初始涂料損壞。劃線(xiàn)應(yīng)向下劃至基材,并相互垂直以生成一個(gè)十字圖案,參見(jiàn)圖1。劃線(xiàn)應(yīng)延伸至測(cè)試區(qū)域外。 每條劃線(xiàn)應(yīng)約為60mm。劃線(xiàn)的橫截面如圖2所示。 重要信息——劃線(xiàn)的邊緣必須與基材垂直。 |

| 5 % flaking / flagning 5%的剝落 |

60 % flaking / flagning 60%的剝落 |

|

|

| B1 | B2 |

圖1:原理布局

Fig. 2Cross section of sample with scribed line / Tvärsnitt av prov med rits

圖2:帶劃線(xiàn)的樣品的橫截面

| As the adhesion test is to be made after moistureexposure (wet adhesion), the test object shall first beexposed in a tropical cabinet in accordance withVCS 1027,33759 for the period specified in therequirement specification. | 由于粘附性試驗(yàn)需在暴露于潮濕環(huán)境中之后進(jìn)行(濕粘附性),測(cè)試對(duì)象應(yīng)首先按照VCS 1027,33759的要求暴露于熱帶機(jī)柜中,暴露時(shí)間參照要求規(guī)格說(shuō)明中的規(guī)定。 |

| For metal substrates, the testing shall be performedimmediately after exposure, without any recovery. Inpractice, this means that the panels can be storedmaximum 60 min in a vessel filled with water of roomtemperature to keep them humid until testing. Theshortest possible time shall be aimed for. | 對(duì)于金屬基材,應(yīng)在暴露之后立即進(jìn)行測(cè)試(無(wú)任何恢復(fù))。在實(shí)踐中,這就意味著面板可在室溫條件下儲(chǔ)存在充滿(mǎn)水的容器中*長(zhǎng)60min,以便保持其在測(cè)試前的潮濕狀態(tài)。時(shí)間盡可能*短。 |

| As far as plastics substrates are concerned, they shall be stored for 1 h in a constant-temperature controlled cabinet at standard atmosphere (23 ± 2 °C, 50 ± 5 % RH) instead of storage in a water-filled vessel. This shall be done to allow the material to recover. The testing shall then take place within approx. 15 min. | 如果涉及塑料基材,應(yīng)在標(biāo)準(zhǔn)大氣環(huán)境中(23±2℃,50±5%RH)將其儲(chǔ)存在恒溫控制機(jī)柜中1h,而不是充滿(mǎn)水的容器。這樣做的目的是讓材料恢復(fù)。然后應(yīng)在約15min內(nèi)進(jìn)行測(cè)試。 |

| The scribing shall be made prior to the moistureexposure. For metal with paint or other organicsurface coating, scribing can alternatively be madeafter moisture exposure. In the latter case, anagreement shall be made between test requester andtest responsible. The report shall state when thescribing was made. | 應(yīng)在暴露于潮濕環(huán)境中之前進(jìn)行劃線(xiàn)。對(duì)于帶有油漆或其他有機(jī)表面涂層的金屬,也可以在暴露于潮濕環(huán)境中之后進(jìn)行劃線(xiàn)。對(duì)于后者,測(cè)試請(qǐng)求人和測(cè)試負(fù)責(zé)人應(yīng)達(dá)成協(xié)議。報(bào)告中應(yīng)說(shuō)明進(jìn)行劃線(xiàn)的時(shí)間。 |

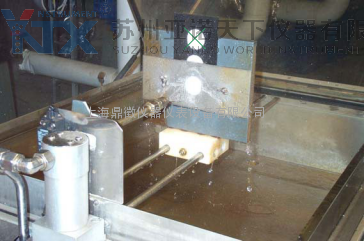

| 4 Test procedure | 4 測(cè)試程序 |

| Place the test object in the test piece holder. Then fixthe test piece holder’s hole (∅ 40 mm) centrally abovethe initial damage. It is important that the scribedcross is correctly positioned in front of the jet, see fig.3. The following parameters apply; the nominal valuesare target values: | 將測(cè)試對(duì)象放在試樣固定器上。然后將試樣固定器的孔(∅40 mm)固定在初始損壞中心上方。將劃出的十字標(biāo)記正確地放置在噴嘴的前方非常重要,參見(jiàn)圖3。下列參數(shù)適用;標(biāo)稱(chēng)值即為目標(biāo)值: |

| − The water jet shall sweep over the test surface(± 20 mm) with an angle of deflection of 5,6° fromthe nozzle tube’s centre of rotation(N.B. – No parallel displacement) | − 噴水器應(yīng)以5.6°的偏向角從噴嘴管的旋轉(zhuǎn)中心掃過(guò)測(cè)試表面(±20mm)(注意:無(wú)平行位移) |

| − Distance between nozzle and test surface (90°):100 ± 3 mm | − 噴嘴和測(cè)試表面之間的距離(90°):100 ± 3 mm |

| − Water pressure: 120 ± 3 bar | − 水壓:120 ± 3 bar |

| − Water flow: 15,0 ± 0,3 l/min | − 水流量:15.0± 0.3 l/min |

| − Water temperature: 50 ± 5 °C | − 水溫:50 ± 5℃ |

| − Number of sweeps during 30 s: 30 ± 2 | − 30秒內(nèi)的清掃次數(shù):30 ± 2 |

| − Sweeping width: ± 20 mm (diameter of the testpiece holder’s centre hole) | − 清掃寬度:± 20 mm(試樣固定器的中心孔的直徑) |

| If the test panel temperature varies between thedifferent sprayings, the result can sometimes beinfluenced. Before spraying, the panel shall thereforebe of room temperature 18 - 28 °C. This applies toeach cross. | − 如果測(cè)試面板的溫度在不同噴水過(guò)程中發(fā)生變化,則有時(shí)會(huì)對(duì)結(jié)果產(chǎn)生影響。因此,在噴水前面板應(yīng)為室溫(18-28℃)。該項(xiàng)要求適用于所有十字標(biāo)記。 |

| 5 Assessment | 5 評(píng)估 |

| After completed test, the object shall be wiped dry and the extension of the paint damage shall be established. The test result shall be given in per cent flaked paint surface. 100 % is defined as the circular area (0 40 mm) centred on the scribed cross, see fig. 1, (1256 mm2) minus the scribed line area of 40 mm2. | 完成測(cè)試后,將測(cè)試對(duì)象擦干并確定油漆損壞的延伸。測(cè)試結(jié)果應(yīng)以剝落的油漆表面的百分比給出。100%定義為以劃出的十字標(biāo)記為中心的圓面積(Φ40mm),參見(jiàn)圖1(1256mm2),減去劃線(xiàn)的面積(40mm2)。 |

| The requirement shall be met for each scribed cross. Mean values for the entire part/panel shall NOT be calculated. | 每個(gè)劃出的十字標(biāo)記均應(yīng)滿(mǎn)足要求。不應(yīng)計(jì)算整個(gè)零件/面板的平均值。 |

| 6 Report | 6 報(bào)告 |

| The test report shall include the following: | 測(cè)試報(bào)告應(yīng)包含以下內(nèi)容: |

| a) Type and designation of test material | a) 測(cè)試材料的類(lèi)型和名稱(chēng) |

| b) Test result in per cent (for each test objectrespectively). Ranges can be given if the result is approved according to the requirement specification. The number of rejected samples shall be noted. | b) (每個(gè)測(cè)試對(duì)象對(duì)應(yīng)的)測(cè)試結(jié)果,百分比。根據(jù)要求規(guī)格說(shuō)明,如果批準(zhǔn)了結(jié)果,則可以給出范圍。應(yīng)記錄被拒絕的樣品的數(shù)量。 |

| c) Testing in accordance with VCS 1029,54719 | c) 按照VCS 1029,54719的要求執(zhí)行的測(cè)試 |

| d) If scribing was performed before or after moisture exposure, if any | d) 劃線(xiàn)在暴露于潮濕環(huán)境中之前還是之后執(zhí)行(如有)。 |

| 7 Calibration | 7 校準(zhǔn) |

| Unless otherwise specified, calibration and inspection of the nozzle’s spray pattern shall be made with an interval of 90 days. | 除非另有規(guī)定,否則應(yīng)以90天的時(shí)間間隔執(zhí)行噴嘴的噴射形式的校準(zhǔn)和檢查。 |

| Calibration is performed by subjecting a test panel (approx. 100 x 200 mm) of low-density polyethylene as per STD 1211,05or equivalent material to high- pressure cleaning for 30 s without the use of a test piece holder. The nozzle must not oscillate. The following parameters apply: | 校準(zhǔn)的執(zhí)行方法為:對(duì)低密度聚乙烯測(cè)試面板(約100 x 200 mm)(按照STD 1211,05)或者其他等效材料執(zhí)行高壓清洗30s,不使用試樣固定器。噴嘴不得振動(dòng)。下列參數(shù)適用: |

| − Angle between nozzle and test surface: 90° | − 噴嘴和測(cè)試表面之間的夾角:90° |

| − Distance between nozzle and test panel: 100 mm ± 3 mm | − 噴嘴和測(cè)試表面之間的距離:100 mm ± 3 mm |

| − Water pressure: 120 bar ± 3 bar | − 水壓:120 bar ± 3 bar |

| − Water flow: 15,0 ± 0,3 l/min | − 水流量:15.0 ± 0.3 l/min |

| − Water temperature: 50 ± 5 °C | − 水溫:50 ± 5℃ |

| The nozzle’s spray pattern is determined by measuring the length and width of the damage on the test panel caused by the spraying as well as checking its appearance. | 通過(guò)測(cè)量測(cè)試面板上因噴水造成的損壞的長(zhǎng)度和寬度,以及檢查其外觀(guān)等方式確定噴嘴的噴射形式。 |

| To be approved, the spray pattern shall be continuous, have a length of 63,0 ± 5 mm and a width of min 3,0 mm, and it shall be contained between two parallel lines, 7,0 mm apart (see fig. 4). | 待批準(zhǔn):噴射形式應(yīng)連續(xù),長(zhǎng)度為63.0 ± 5 mm、寬度為3.0mm,并且其應(yīng)處于兩條間隔為7.0mm的平行線(xiàn)之間(參見(jiàn)圖4)。 |

圖3:十字標(biāo)記以圖示的形式顯示了與垂直的扁平射流有關(guān)的劃線(xiàn)十字損壞的位置。

Fig. 4 Damage from spray

圖4:噴射造成的損壞

- 創(chuàng)傷骨科應(yīng)用 2023-12-14

- 安全鞋外底剛性試驗(yàn)機(jī) 2023-04-23

- DIN55662涂層和清漆耐高壓水沖擊試驗(yàn) 2023-04-01

- Ford FLTMBO160-04涂料油漆耐高壓水噴 2023-04-01

- Ford VCS 1029,54719高壓蒸汽噴射試驗(yàn) 2023-04-01

- PV3987高光耐磨測(cè)試方法 2023-03-17

- 馬丁代爾織物耐磨性測(cè)試:ISO 12947最 2023-02-27

- 手機(jī)可靠性測(cè)試包括哪些檢測(cè)項(xiàng)目和標(biāo) 2023-02-27